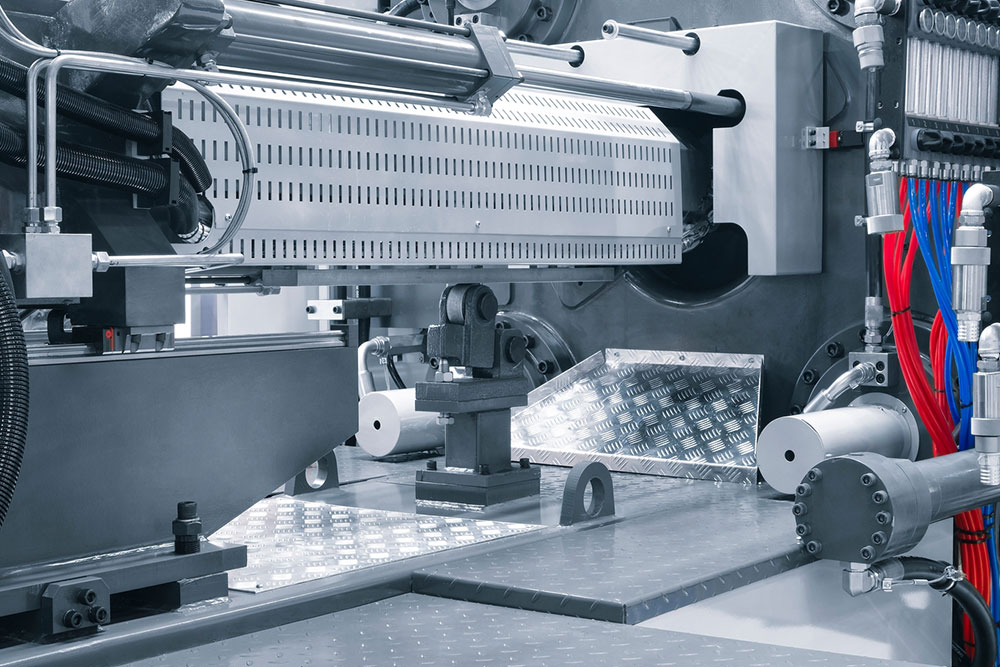

Types and uses of PVC extrusion machines

A PVC extrusion machine helps process a type of plastic called polyvinyl chloride (PVC) and convert it into different products, such as plastic tubes and sheets. It does this by melting PVC and pulling or pushing it through differently-shaped dies or molds. Many manufacturers use PVC extrusion machines because they help make multiple products in less time. That said, choosing the right type of machine and understanding its uses is important for the best outcome.

Types

There are different types of PVC extrusion machines, each with its own features and ways of functioning.

1. Plastic sheet extrusion equipment

These machines help manufacture a PVC product with raw plastics and other raw materials. These materials are melted and sent through a flat die or mold to produce a continuous plastic film. This film is then trimmed into a wide range of plastic products, such as plastic panels, weather stripping, etc.

2. Single-screw extrusion machines

In these machines, a single screw operates a cylinder that combines plastic granules to form a lump. This lump is pushed through a die or mold made in the shape of the final product. One of the most useful benefits of single-screw extrusion machines is that they are relatively cheaper and have a straightforward yet rugged design.

3. Twin-screw extrusion machines

These have two screws that rotate with or against each other. Since they have different configuration options and variations in settings, twin screw extrusion machines are used to manufacture products that require specific features and colors using additives. They are widely used in different industries that manufacture plastic-based products.

Uses

PVC extrusion machines have applications across a variety of industries.

1. Solar industry

Many companies in this industry use plastic extrusion machines to make encapsulation components and solar panel frames. Since extruded plastics are light and more durable, they provide the right support to solar modules, increasing their lifespan. They are also highly resistant to environmental elements, further increasing their durability.

2. Automotive sector

PVC extrusion machines are primarily used to manufacture vehicle parts in the automobile industry. Weather seals, gaskets, interior trim components, and even tubing and hoses for fluid transfer typically require extruded plastic. The advantage of using manufactured extruded parts is that they are more resistant to chemicals, UV exposure, and temperature variations. This increases a vehicle’s safety and prevents it from breaking down too often.

3. Appliance manufacturing

The appliance industry uses PVC extrusion machines to produce handles, gaskets, seals, and other parts. Extruded plastics provide a higher level of insulation and sealing, which leads to better energy efficiency of appliances. Besides this, the extrusion process is quite cost-effective, which allows a manufacturer to make high volumes of similar parts while maintaining quality standards.

4. Construction industry

Extruded plastic is widely used to manufacture parts of windows, doors, and other architectural and building elements. That’s why many contractors in the construction industry invest in PVC extrusion machines. Since extruded plastics are versatile, manufacturers can make construction components that are weather-resistant and thermally efficient.