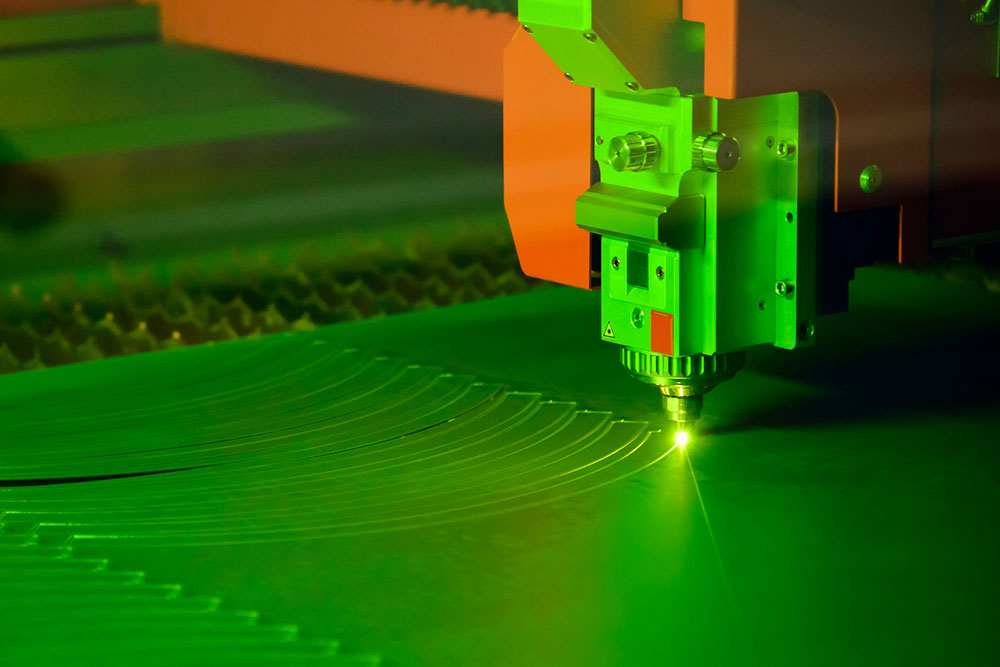

Features and types of laser cutting machines

Laser cutting has proven to be a highly effective method for achieving precise cuts on various materials. This method involves using high-intensity laser beams to cut materials or make markings on their surfaces. Its widespread use across industries is no surprise, as it delivers superior results at a quicker pace compared to traditional cutting methods. Due to their wide range of applications and benefits, laser cutting machines have become indispensable in modern-day manufacturing and design.

Overview

Laser cutting machines are advanced tools that utiliz e a concentrated beam of light known as a laser. The focused laser beam emits intense heat and pressure, enabling it to burn, melt, and vaporize a wide range of materials within seconds. Industries heavily rely on these machines to harness this powerful feature of the laser to distort and precisely slice materials to their exact specifications. This includes durable materials, such as thick metals, which can be challenging to cut using conventional machines. Additionally, the cutting process produces minimal waste or residue since the intense heat generated from the laser effectively melts or vaporizes the material.

Features and uses

- Easy control

Computer numerical control or CNC laser cutting machines are commonly available on the market. This feature allows the operator to control the intensity and direction of the laser, enabling industries to use the machines for multiple purposes, such as cutting or engraving. - Adaptability

One of the most important features of laser cutting machines is their adaptability to different materials, making them useful in various industries. With the right settings, industries can use such machines to work with delicate materials like leather and fabric or hard materials like metal. - Precision

Laser cutting machines can achieve incredibly precise cuts, with widths as narrow as 0.001 inches. - Engraving

The machines can be utilized for engravings on several surfaces, such as metals, acrylic, wood, and leather . Thus, they are commonly used for engraving trophies, creating custom designs on digital devices, designing furniture, and more.

- Cutting

Owing to the machine’s high precision and smooth cutting ability, these machines are often used to cut paper and wood. - Plastic marking

Fiber lasers are commonly used to create permanent marks and prints on engineered plastics. These specific laser machines have the ability to produce marks in different colors by reacting with plastic in specific ways.

Types

- CO2 laser cutter

As the name suggests, CO2 laser cutters use carbon dioxide as a laser medium. These types are widely preferred because they can generate exceptionally powerful beams, suitable for cutting through strong and sturdy materials. - Fiber laser cutter

These laser cutters use fiber-optic cables to precisely concentrate the laser beam on the material. This feature makes them extremely versatile and compatible with almost all types of materials. - Crystal laser cutter

Since these cutters use crystals like neodymium-doped yttrium aluminum garnet (Nd :YAG ) and neodymium-doped yttrium orthovanadate (Nd :YVO ) to produce laser beams, they are called crystal laser cutters. These types of cutters are used in several industries for multiple purposes , including cutting and welding ceramics and metals, marking and engraving on glass and plastics, and doing cosmetic treatments like laser removal. It also has military applications and is used in scientific research.